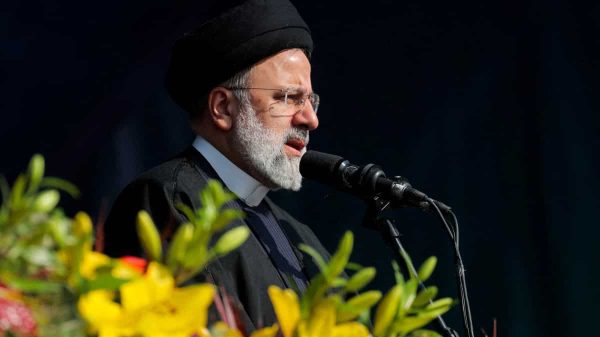

Impact of Baltimore Bridge Collapse

The recent collapse of a major bridge in Baltimore, triggered by a collision with a cargo ship, has sent shockwaves through the supply chain, prompting businesses to swiftly strategize to avert economic repercussions.

Baltimore Bridge Collapse Incident

A massive cargo ship named Dali was crippled by power loss when it crashed into the Francis Scott Key Bridge over the mouth of the Patapsco River at about 1:30 am (0530 GMT). The Singapore-flagged container vessel was heading out of the harbor bound for Sri Lanka at the time.

Economic Fallout and Industry Response

The significance of the Port of Baltimore, highlighted by US Transportation Secretary Pete Buttigieg, shed light on the critical role it plays as the nation’s largest vehicle-handling port. Maryland Governor Wes Moore sounded the alarm, cautioning about the widespread indirect impacts affecting over 140,000 people, in addition to the thousands of port workers directly affected.

- Industry experts are mobilizing to mitigate potential disruptions while acknowledging manageable challenges in the immediate future.

- Analysts predict a partial diversion of cargo to alternative ports, primarily the Port of New York and New Jersey, in response to the suspended operations at the Port of Baltimore.

- The automotive industry emerged as one of the sectors most vulnerable to the disruptions, with major manufacturers like Mazda and Stellantis formulating contingency plans to safeguard their supply chains.

Stakeholder Resilience

Despite the unprecedented challenges posed by the bridge collapse and subsequent supply chain disruptions, stakeholders across industries are rallying together to navigate the uncertainty with resilience.